These sound waves can be propagated in the material in many ways modes. Visual Inspection VT.

Ut Vs Paut What S The Difference Read The Article At Http Bit Ly 2pf0ymw Ndt Paut Ut Phasedarray Ultraso Phased Array Ultrasonic Testing Ultrasonic

Ultrasonic testing UT can be used on ferrous and nonferrous materials and often is suited for testing thicker sections accessible from one side only.

. David Overton Jay Richardson Jason Halsey ABSTRACT In recent years there has been a steady rise in request for alternatives to weld acceptance examinations in lieu of traditional radiography in both fossil and nuclear generating plants. This technique has been accepted as an inspection method for welds since the 1940s. Display and Rendering Differences.

Can you guys provide me with any other reasons to perform a UT test vs an RT test and what are advantages and dis-advantages of both. Visual Inspection VT Magnetic Particle Testing MPT Dye Penetrant Liquid Testing DPI Radiographic Testing RT Ultrasonic Testing UT. Austenitic stainless steel is used in industries for its superior mechanical properties.

The NDT nondestructive testing methods are. Weld inspectors are trained to understand the images captured on radiographic film. Since the 1940s the accepted inspection method for structural welds in the US.

What is UT and RT in welding. The re-test by 10 RT is because the clients do not as always happens trust the little green squiggly lines on the UT set or the operators. Oct 21 2019 1 comment.

Real Time Non-Destructive Testing Methods of Welding This work presents a review of. Ultrasonic testing for building structures. Topic Welding Industry Inspection Qualification UT Vs RT By Ariel D C Date 12-16-2005 0601 Need Expert Advice- Contract Spec asks for 100 UT RT on butt joints and to assess in accordance with AWS D11 Actual event.

In lieu of radiographic testing RT UT weld inspection is a reliable solution for detecting cracks and other discontinuities in stainless steel. There are a variety of weld testing methods each with its own advantages and disadvantages. Both radiography and ultrasonic testing are valuable in non-destructive testing of welds and materials.

Ultrasonic testing UT can be used on ferrous and nonferrous materials and often is suited for testing thicker sections accessible from one side only. Maintenance for engine parts. Destructive Testing- Fracture test Bend Test Macro test Tensile Test etc.

2 Granted that B319 Building Services piping is very lienient as far as NDT requirements are concerned it actually doesnt require it at all but has a suggested minimum quality level However since all welds. Common UT Weld Inspection Applications. Weld testing methods are necessary to ensure the quality of a weld.

RT uses X-rays to create a 3-D image of the weld whereas UT uses sound waves to find discontinuities in the weld. Thereafter RT was done on the. UT and RT can detect both external and internal discontinuities while MPI DPI and VT can only detect external defects.

Ultrasonic Testing UT. To detect location and size of internal defect using echo uttering by the ultrasoic equipment. Longitudinal waves Figure 6 are also called as straight or compressional waves.

There are five basic NDT methods used to detect weld defects. In general it can detect finer linear or planar defects than can RT. UT and RT results in some cases cannot be the same that is why we perform sometimes both UT and RT together for the same joint.

Radiographic Testing RT. Magnetic Particle Testing MT. Determining whether using ultrasonic testing UT in lieu of RT for new construction is feasible Determining whether performance-based criteria are needed for RT.

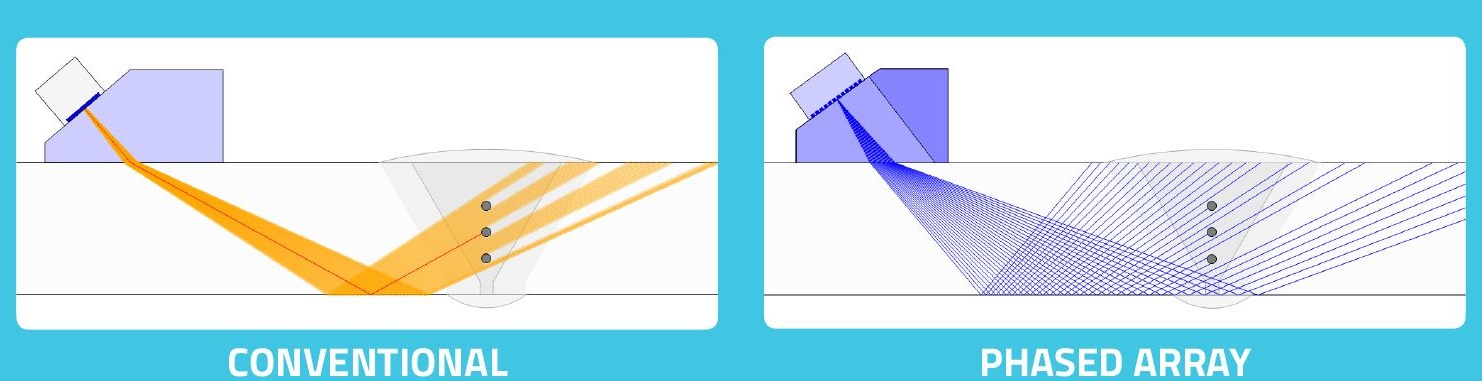

UT makes use of mechanical vibrations similar to sound waves but of higher frequency. By superadmin on September 13 2019 in Blog. An ispection requires a 100 UT inspection of an 80-90mm butt weld in steel plate followed by a re-test of the same weld by 10 RT.

Three basic modes of propagation of sound energy in metals are being used in Ultrasonic test these modes are. In general it can detect finer linear or planar defects than can RT. For ultrasonic equipment the trained eye sees the peaks and signal furrows the wrinkles and gutters and those return echoes all have meaning.

UT was carried out on 1 thk butt joint groove weld and the result was satisfactory. With the help of this method we can detect hidden flaws or discontinuities present in welds such as cracks porosity blowholes slag flux or oxide inclusions lack of fusion incomplete penetration Mismatch and tungsten inclusion etc. UT versus RT weld inspection on butt welds.

This content is for Company Representative Premium Member Standard Member NDT Professional Inspector Rope Access Welding Inspector Inspection Engineer QA QC Professional and Welding Professional members only. Conditioning or grinding also is used to smooth out these areas for surface inspection. A major advantage of radiography compared to other inspection techniques is the availability of objective quality.

This initial report is a preliminary study on these issues and is a first step towards. Surface cleaning is necessary to prepare the welds for either MT or PT. Navy has been radiography RT.

NPP weld inspection applications. Eddy Current Testing ET not used in field inspection Acoustic Emission Testing AET not used in field inspection Phased Array Ultrasonics. Inspection for quality of welding.

RT and UT are volumetric tests. We conduct ultrasonic testing for various weldingpipeline of boiler tube. This is done with a permanent or electromagnet induced magnetic field such as from a current-carrying.

Porosity in UT might not cause rejection but RT may. It works as its name applies by having the tester create a magnetic field around the object being inspected. Radiography testing RT is one of the most widely used non-destructive test NDT methods.

THE PRACTICAL USE OF UT IN LIEU OF RT IN THE POWER INDUSTRY Structural Integrity Associates Inc. These waveforms are the simplest of all other waveforms. A beam of ultrasonic energy is directed into the object to be tested.

Just because two of them having different limitation. Magnetic Particle Inspection sometimes referred to as Magnetic Particle Testing is a very common and easy-to-use NDT technique. Welding Inspection Terms Definitions.

They see the discontinuities and weld defects in the image. Both methods also require a high skill level and training to ensure accurate readings and avoid dangers as well especially in radiography where X-rays or gamma rays are. Cracklamination orientated perpendicular to the RT source radiation direction will not show.

Which One Is Better. Weld Testing methods can be classified into two main types. Download Table Comparison between RT ET and UT methods from publication.

Exposure to extreme conditions can however lead to flaws. Non-Destructive Testing- Visual Testing. Liquid Penetrant Testing LT.

Comparison Between Rt Et And Ut Methods Download Table

Comparison Between Rt Et And Ut Methods Download Table

Radiography Test Rt Welding Ndt

Defects Types Ultrasonic Testing Defects Types Ultrasonic Testing Ultrasonic Industrial Radiography

Fun Fact Friday The Differences Between Radiographic Ultrasonic Weld Testing

0 comments

Post a Comment